If you visit a history museum, you’ll notice a lot of older items and products were made of metal. It wasn’t until the 1950s that plastic materials became popular for so many things. During the 1950s, many items that were previously made from metal started to be made, instead, from plastic. Many manufacturers made the change from metal to plastic. This “conversion” took over most industries!

Plastic Parts in the Modern World

Plastic has more advantages and benefits than metal for most items and products. For instance, plastic blends can be customized in order to meet demands whether they be environmental, structural or operational. With good design and the right choice of material, some plastic components will outperform metal! It also turns out that plastic items are strong and durable, and don’t take as long to make as metal items do.

If you want to get more specific, one of the main reasons metal to plastic conversions are en vogue today is because plastic can include additives which increase the overall performance of that plastic including things like tensile strength, friction, and scratch/flame resistance. Also, plastic can be made to be environmentally-friendly, and safe enough to use in things like medical supplies and food distribution.

When You Should Consider Metal to Plastic Part Conversions

What are some reasons to consider metal to plastic part conversions? Thanks to today’s technology, predictive design tweaks can be made and one can expect stronger performance outcomes. Need to consolidate parts? Or you want to integrate and accommodate complex shapes and geometries? Plastic is the best choice! Plastic is also lighter than metal. And, when it comes to aesthetics, with plastic you get a variety of colors, as well as textures and surface finishes which can look quite visually appealing compared to the relatively boring metal look.

Metal parts tend to be bigger and bulkier than plastic parts. If you’re looking to reduce size, weight and thickness, make the metal to plastic part conversion. Plastic parts can be reliable and robust and able to hold tight tolerances. And they’re resistant to impact, heat and corrosion, too, so that’s a good bonus.

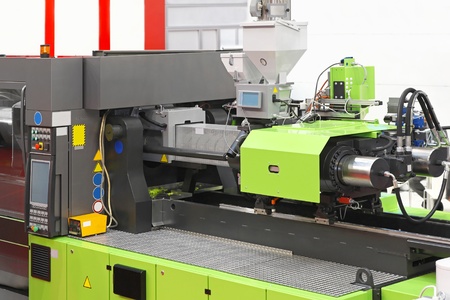

Bridgville Plastics can make plastic parts for you. Unlike metal parts, plastic parts don’t need to be coated or painted. This makes them pretty much maintenance-free. Plus, plastic parts can be made more quickly than their metal counterparts. Most plastic parts are made using mechanized automation.

If you’re wanting to reduce production time and costs, consider metal to plastic part conversions. The costs of plastics generally remain stable while the price of metals highly fluctuates. Plastics also offer energy savings, lower shipping and operating costs, and reduced scrap and waste.

Considering metal to plastic part conversions? Call Bridgville Plastics of Michigan and discuss your needs. The number is 269-465-6516. You can also use the online contact form, here.