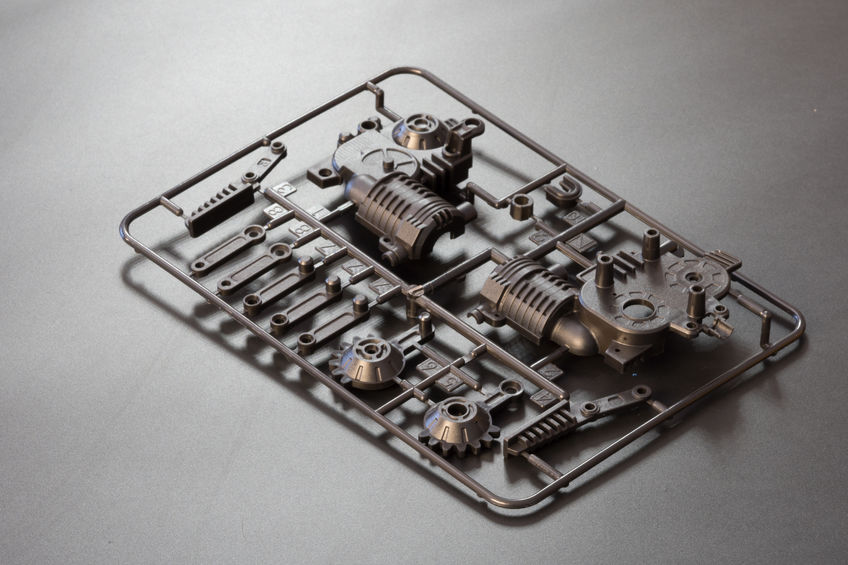

Simply put, insert molding refers to the injection molding process that conjoins several types of materials into a single finished part. The different materials could include a wide range of items, including but not limited to screws, brackets, threads, clips and more. These materials are made from an assortment of metals, including aluminum, stainless steel, copper and more.

Insert moldings for plastic parts are used by businesses in many industries, including those in the medical, automotive, electronics, HVAC and aerospace industries.

Reasons to Choose Insert Moldings

So why should you consider choosing insert moldings for your plastic parts? Well for starters, insert molding helps companies create a better end product, since they’re able to assimilate different materials into it. Ultimately, it will help designers create a more robust and durable end product, which thereby extends its lifespan.

Furthermore, insert molding helps reduces costs, since you need not worry about molding metal elements after the plastic ones are added. As well, if helps create faster assembly times and reduces the overall weight and size of the parts of the end product.

Overall, insert molding for plastic parts provides the best of both world; it’s a cost effective strategy that helps you save money, while also helping you create a superior end product that is comprised of different materials.

If you’re in the market for insert moldings for plastic parts, Bridgville Plastics of Stevensville, MI is here to help. We have over 32 years of industry experience and have worked on all sorts of projects. With design assistance and metal to plastic conversion services, we can help you every step of the way regarding your plastic insert molding needs.

To learn more about our services, contact us today.